Pharmaceuticals Filling Solutions

The pharmaceutical industry is experiencing rapid growth, driven by ongoing research and development. It is a vital sector for both developed and developing countries, providing essential health and medication services. Recent advancements in medical science have created a demand for advanced machinery to support bulk drug production, processing, and packaging.

Pharmaceutical products often require special precautions during the packaging process due to their ingredients and intended use. One of the key areas of focus is the filling process, as liquid fillers are the machines that directly interact with the product. Additionally, other components of the packaging system may need modifications to prevent contamination.

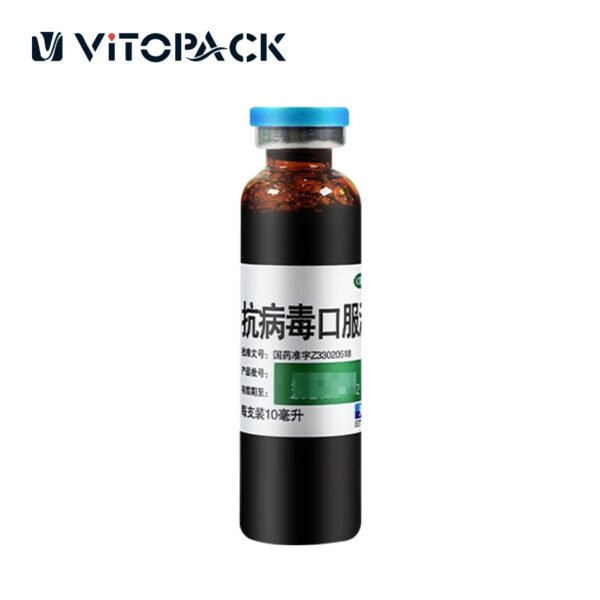

Pharmaceutical filling machines play a crucial role in modern manufacturing. Syringe filling equipment is designed for large-scale operations, ensuring sterility and accurate volume dispensing. Vial filling machines can fill hundreds of vials per minute while minimizing product loss and maintaining consistent volume. Pharmaceutical checkweighers are essential for identifying defective tablets, ensuring that the final product meets quality standards before packaging. A variety of filling equipment streamlines the pharmaceutical manufacturing process.

While this overview highlights filling machines in the pharmaceutical sector, it is important to note that pharmaceutical applications often have more stringent requirements compared to those in the nutraceutical, biomedical, and diagnostic specialty chemicals industries. Many pharmaceutical processes demand comprehensive regulatory control over all aspects of packaging, including filling, container closing, and handling. This necessitates more than just a simple filling machine; a multifunctional system known as a “monoblock” can perform all necessary functions.

In cases where containers are easier to manage, a standalone peristaltic filling machine may suffice for many applications in the biomedical, diagnostics, and nutraceutical sectors, with some overlap into pharmaceuticals. Typically, these systems utilize peristaltic pumps, small pistons, or micro positive displacement pumps for liquid delivery. All systems are equipped with digitally encoded servo drives to enhance accuracy and ensure proper documentation.

Product Examples

- Cough Syrups

- Paracetamol Suspension

- Cold & Flu Remedies

- Digestive Remedies

- Vitamin Supplements

- Sports Nutrition

- Acne Treatments

- Eczema Creams

- Wart Remover

- Lubricants

- Eye Drops

- Ear Drops

- HiBiSCRUB

- Zoflora

- Anesthetics

- Pathology

- Cytology

- Inhalers

- Paracetamol

- Vitamins

- Minerals

- Food Supplements

- Solvents

- TCP

Pharmaceuticals Filling Solutions

The pharmaceutical industry is experiencing rapid growth, driven by ongoing research and development. It is a vital sector for both developed and developing countries, providing essential health and medication services. Recent advancements in medical science have created a demand for advanced machinery to support bulk drug production, processing, and packaging.

Pharmaceutical products often require special precautions during the packaging process due to their ingredients and intended use. One of the key areas of focus is the filling process, as liquid fillers are the machines that directly interact with the product. Additionally, other components of the packaging system may need modifications to prevent contamination.

Pharmaceutical filling machines play a crucial role in modern manufacturing. Syringe filling equipment is designed for large-scale operations, ensuring sterility and accurate volume dispensing. Vial filling machines can fill hundreds of vials per minute while minimizing product loss and maintaining consistent volume. Pharmaceutical checkweighers are essential for identifying defective tablets, ensuring that the final product meets quality standards before packaging. A variety of filling equipment streamlines the pharmaceutical manufacturing process.

While this overview highlights filling machines in the pharmaceutical sector, it is important to note that pharmaceutical applications often have more stringent requirements compared to those in the nutraceutical, biomedical, and diagnostic specialty chemicals industries. Many pharmaceutical processes demand comprehensive regulatory control over all aspects of packaging, including filling, container closing, and handling. This necessitates more than just a simple filling machine; a multifunctional system known as a “monoblock” can perform all necessary functions.

In cases where containers are easier to manage, a standalone peristaltic filling machine may suffice for many applications in the biomedical, diagnostics, and nutraceutical sectors, with some overlap into pharmaceuticals. Typically, these systems utilize peristaltic pumps, small pistons, or micro positive displacement pumps for liquid delivery. All systems are equipped with digitally encoded servo drives to enhance accuracy and ensure proper documentation.

Product Examples

- Cough Syrups

- Paracetamol Suspension

- Cold & Flu Remedies

- Digestive Remedies

- Vitamin Supplements

- Sports Nutrition

- Acne Treatments

- Eczema Creams

- Wart Remover

- Lubricants

- Eye Drops

- Ear Drops

- HiBiSCRUB

- Zoflora

- Anesthetics

- Pathology

- Cytology

- Inhalers

- Paracetamol

- Vitamins

- Minerals

- Food Supplements

- Solvents

- TCP