Injection Vial Filling Solution

In the world of pharmaceuticals, vials play a critical role. These small, typically glass or plastic containers are essential for storing and delivering a wide range of medications, from life-saving injections to delicate vaccines. Understanding the nuances of vials is crucial for both manufacturers and healthcare professionals.

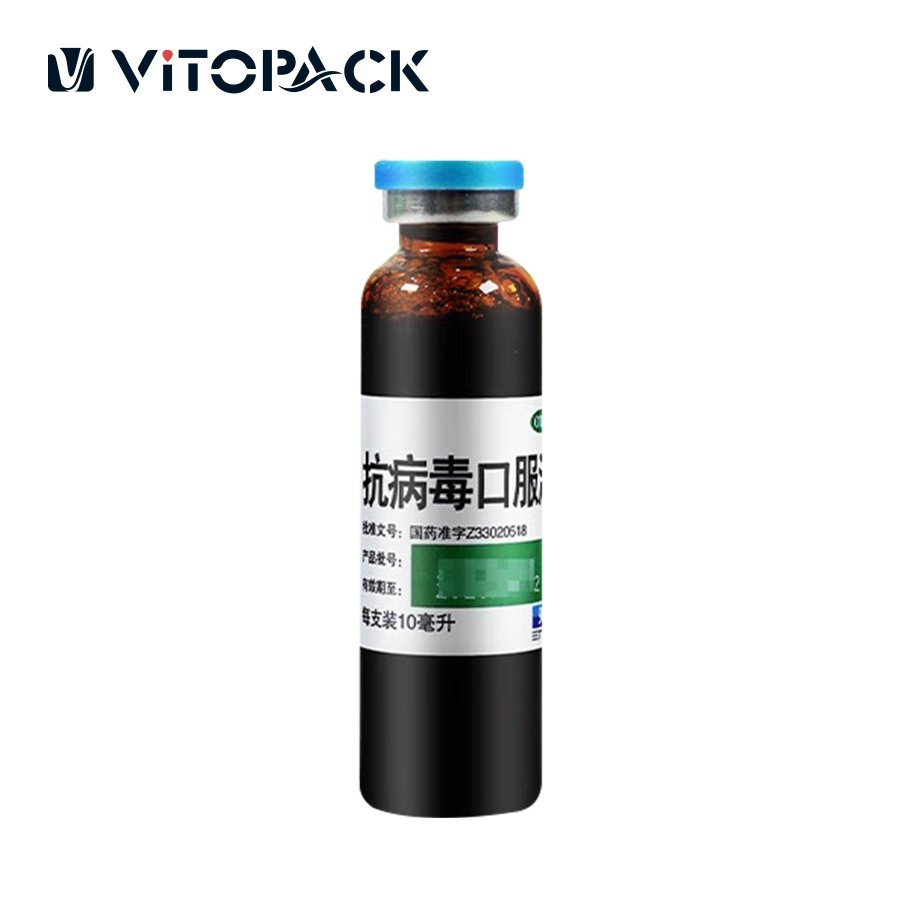

A vial, sometimes referred to as a phial or flacon, is a small container made of glass or plastic, commonly used to store medications in the form of liquids, powders, or capsules. These versatile vessels are not only essential for pharmaceuticals but also serve as scientific sample containers.

Vials come in various types, including single-dose vials and multi-dose vials, each designed for specific uses. For instance, an injection vial is intended for one-time use, containing liquid medication meant for parenteral administration—essentially, injections or infusions—tailored for a single patient during a specific procedure.

The Role of Automatic Injection Liquid Vial Filling Machines

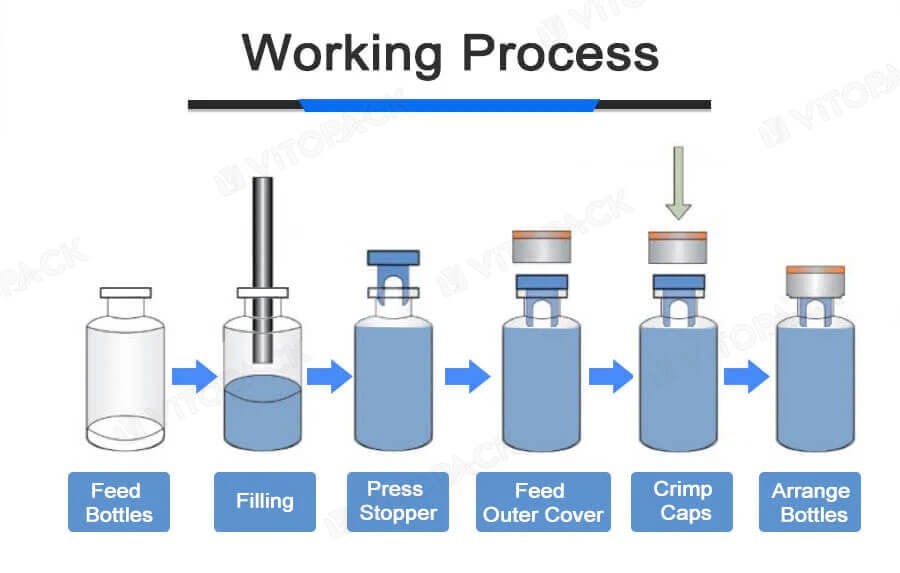

To streamline the process of filling these vials, we have the Automatic Injection Liquid Vial Filling Machine. This highly efficient machine is designed specifically for filling injection liquids into vials, making it a preferred choice for round containers.

One of the standout features of this machine is its ability to place rubber stoppers on top of the vials, ensuring that the contents remain protected from contaminants. As one of the leading manufacturers of vial filling machines, we pride ourselves on delivering high-precision operations that minimize waste and spillage.

With the capability to handle a significant number of vials per hour, our vial liquid filling machine is engineered for excellent workability, making it an invaluable asset in any pharmaceutical or laboratory setting. Experience the efficiency and reliability of our machines, and ensure your vials are filled with precision and care.

Filling and Capping Machine

Vitopack’s Advanced Technology

Vitopack has always been at the forefront of technological innovation in the pharmaceutical packaging industry. Our vial filling machines incorporate several cutting-edge features:

- Nozzle Design: Our precision-engineered nozzles ensure consistent and accurate filling, minimizing product loss and ensuring optimal product quality.

- Contamination Control: Advanced filtration systems and cleanroom design prevent contamination throughout the filling process, safeguarding product integrity.

- Flexible Configuration: Our machines can be customized to accommodate a wide range of vial sizes, shapes, and filling volumes, providing maximum flexibility for our clients.

- Data Integrity: Integrated data management systems capture critical process parameters, ensuring compliance with regulatory requirements and enabling traceability.

Ensuring Quality and Compliance

Quality is at the heart of everything we do at Vitopack. Our vial filling machines are designed and manufactured to meet the stringent requirements of regulatory bodies such as the FDA and EMA.

- GMP Compliance: Our manufacturing processes adhere to Good Manufacturing Practices (GMP) guidelines, ensuring the highest standards of quality and safety.

- Validation Services: We offer comprehensive validation services to ensure that our equipment meets your specific process requirements and regulatory standards.

- Material Compatibility: Our machines are designed to handle a wide range of materials, including glass, plastic, and rubber, ensuring compatibility with various pharmaceutical formulations.

Reduced Costs and Increased Efficiency

By investing in a Vitopack vial filling machine, you can:

- Reduce labor costs: Automate repetitive tasks, freeing up your staff for more value-added activities.

- Minimize product waste: Precision filling and efficient processes reduce product loss.

- Improve overall equipment effectiveness (OEE): Our machines are designed for maximum uptime and minimal downtime.

- Accelerate time-to-market: Streamlined processes and efficient validation enable faster product launches.

Customer Support and Service

Vitopack is committed to providing exceptional customer support throughout the entire product lifecycle. Our services include:

- Installation and commissioning: Our experienced engineers will ensure seamless installation and startup of your equipment.

- Training: We provide comprehensive training to your operators to maximize productivity and minimize downtime.

- Maintenance and service: Our dedicated service team is available to provide ongoing maintenance and support.

In Conclusion

Vitopack offers a comprehensive range of vial filling solutions designed to meet the unique needs of the pharmaceutical industry. Our commitment to quality, innovation, and customer satisfaction sets us apart. By partnering with Vitopack, you can ensure that your pharmaceutical products are produced efficiently, consistently, and in compliance with the highest industry standards.

Get instant Quote

Instant Quotes Tailored for You!