Perfume Filling Solution

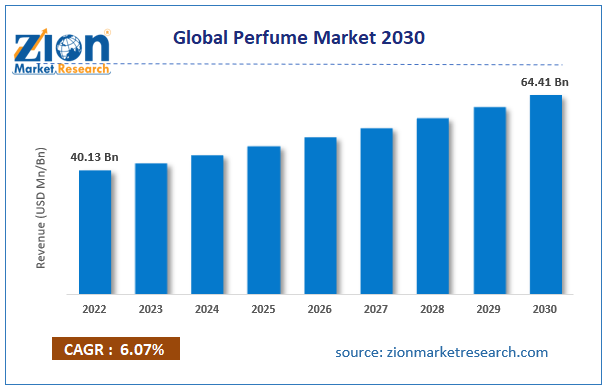

Perfume is a mixture of fragrant essential oils or aroma compounds (fragrances), fixatives and solvents, usually in liquid form, used to give the human body, animals, food, objects, and living-spaces an agreeable scent.[1] Perfumes can be defined as substances that emit and diffuse a pleasant and fragrant odor. They consist of manmade mixtures of aromatic chemicals and essential oils.Perfumes are always popular, so that’s why we need to understand perfume filling solutions [From Wiki].

In the perfume production process, selecting the right “perfume filling solution” is crucial. As a popular personal care product, perfume’s packaging quality directly affects its market image and consumer experience. An efficient and precise filling process is crucial for ensuring product quality. Whether it’s glass or plastic bottles, spray or roller bottles, professional filling equipment is needed to guarantee production efficiency and product consistency. However, perfume filling also faces unique challenges, such as:

- Filling safety for flammable liquids

- Cross-contamination between different scents

- Capping various spray heads

- Stable filling of irregularly shaped bottles.

Types and Selection of Perfume Filling Machines

When selecting a perfume filling machine, factors such as production scale, product characteristics, and budget must be considered. Common types of filling machines include:

- Piston filling machines: Suitable for high-precision filling, but cleaning is more complex.

- Peristaltic pump filling machines: Suitable for small-batch, multi-variety production, easy to change tubing, avoiding cross-contamination.

- Gravity filling machines: Suitable for low-viscosity liquids, simple structure, and low cost.

Vitopack Perfume Filling Solutions

Vitopack is committed to providing high-quality filling and packaging equipment for the perfume industry. Our perfume filling machines are designed to be flexible, meeting the needs of different production scales and product characteristics. We offer:

- Customized filling solutions to meet your specific needs.

- Efficient and stable equipment to improve production efficiency.

- Easy-to-operate and maintain machines to reduce operating costs.

Vitopack designs and builds filling machines and packaging equipment for perfume. Our perfume filling machines are designed to meet the changing needs of the perfume industry. We manufacture the ideal machinery to handle your perfume filling needs and meet your production goals.”

Complete Perfume Packaging Systems: From Filling to Labeling

In addition to filling machines, a complete perfume packaging system also includes:

- Capping machines: Suitable for various spray head specifications, ensuring sealing.

- Labeling machines: Achieving precise labeling, enhancing product image.

- Conveyor systems: Achieving production line automation.

Install A Full System Of Perfume Filling Equipment. Perfume is nearly water-thin and works with many of our liquid packaging machines designed to handle low-viscosity products. Along with perfume filling equipment, we carry a variety of other liquid packaging machinery that can handle perfumes and many other liquids. We have equipment available for nearly every aspect of a perfume packaging system.

Common Challenges and Solutions in Perfume Filling

- Filling of flammable liquids: Choose explosion-proof filling machines to ensure production safety.

- Cross-contamination of scents: Use peristaltic pump filling machines for easy tube replacement.

- Filling of irregularly shaped bottles: Customize fixing molds to ensure filling accuracy.

- Capping of various spray heads: Change capping chucks to adapt to different sizes of spray heads.

Filling of Flammable Liquid. Filling of Various Scents. Capping of various spray caps. Filling of bottles that cannot stand upright.

Vitopack Product Advantages and Technical Features

- Uses constant liquid-level working principle to ensure packaging quality.

- Can simultaneously press collar rings and crimp spray heads.

- Can be equipped with a vibratory bowl sorter for automatic cap arrangement.

- Suitable for small and medium-scale liquid product production.

Use constant liquid-level working principle, this ensures packaging quality. Can press collar ring and crimp spray caps at the same time. Vibratory bowl sorter can be equipped with to move and orient perfume caps. Suitable for small & medium scale production of liquid products

Product Recommendation:

Filling and Capping Machine

If you are interested in our perfume filling solutions, please contact us immediately. Our expert team will provide you with professional consultation and support.

Get instant Quote

Instant Quotes Tailored for You!